XLANCE® makes anything elastic

XLANCE® makes elasticity durable

The science behind XLANCE®

The polymers

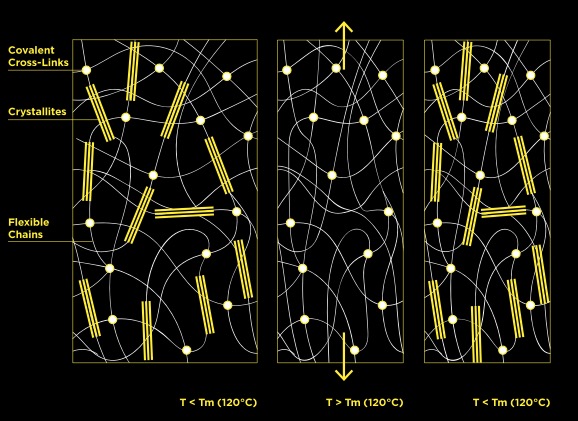

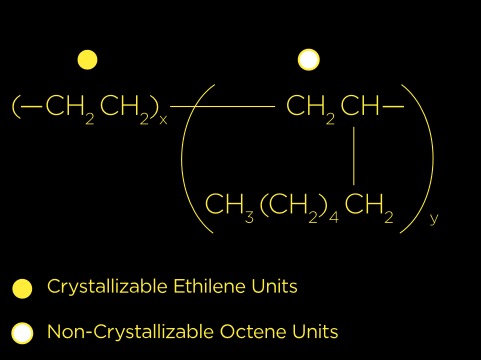

XLANCE® is a polyolefin-based elastic yarn. More specifically, it is based on copolymers of crystallizable ethylene and non-crystallizable 1-octene monomers. These copolymers, at the solid state, build an elastomeric network, where the crystallites serve as reinforcements and act as physical crosslinks to connect the flexible amorphous chains.

The links

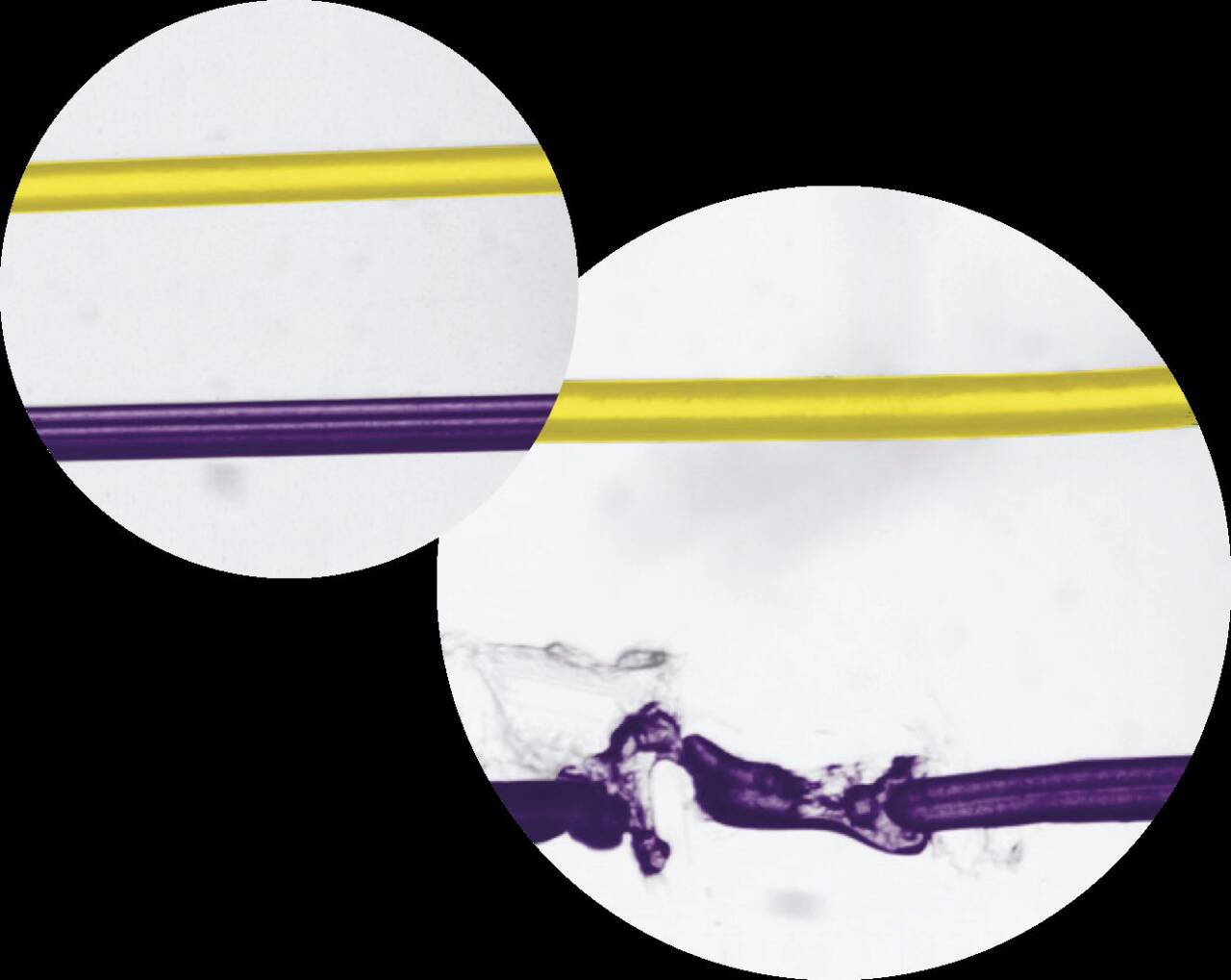

After spinning, XLANCE® undergoes a process to form covalent crosslinks, with the aim to provide the fiber extra thermal stability and mechanical integrity beyond the crystal melting point (i.e. 120°C). Unlike the covalent crosslinks, which are permanent in nature, the crystallites serve as thermally reversible links: at temperatures above their melting point (i.e., 120°C), they disappear, enabling some degree of formability, and re-form upon cooling back, thus allowing fiber setting.